By reducing human error, liquid packaging machines assist minimize solution waste, causing substantial Price personal savings. Organizations gain from a streamlined course of action that lowers operational costs while maximizing output.

Filling machinery & processing machinery for liquid items & turnkey liquid packaging strains, continuous stream electronic Mixing machinery, automatic batch devices & transfer programs for liquid merchandise

The powder filler machine ordinarily employs an auger technique for that controlled dispensing of the powder. An auger is usually a helical-shaped screw that rotates to move the powder in the hopper towards the filling nozzle. These machines are suited to filling spices, powders, and granules.

The VEVOR Chamber Vacuum Sealer DZ-260C is designed with longevity in your mind. It’s made with commercial-quality chrome steel, removing the issues of rust appearing on the machine after a handful of months of use.

Exactly what are the likely Charge savings and return on financial commitment (ROI) we will assume by buying present day food packaging machines? Investing in modern day food packaging machines can yield sizeable Expense cost savings along with a promising return on financial investment (ROI) by way of a range of aspects:

Preserve your individual and do the job purchases separate. Create and customize a multi-user account to empower your employees to buy the things they want, though monitoring devote.

Lintyco VFFS packaging Machine offer a wide varity of software.It might be an outstanding choice for packaging specific frequent fluids, supplying a affordable Resolution that does not compromise high quality.

What are The real key aspects to look at when deciding on a food packaging machine for just a food processing facility? When choosing a food packaging machine for the food processing facility, quite a few important variables should be regarded as like:

Leak screening – Conduct plan leak checks stressed on sample pouches to make certain pouch integrity.

Liquid packaging machines are indispensable for industries coping with huge volumes of liquid solutions, ensuring efficiency, consistency, and adaptability across diverse food packaging machine manufacturers applications.

Day Printing —— In accordance with the real creation and packaging wants, different types of coding machines are configured to print the date and batch amount over the packaging bag.

Help you save five% or maybe more with Amount Discounts on a lot of products and solutions, starting off at just two units of a similar item.

Our machines’ strong design enables them to package in damp problems without rusting or malfunctioning. Even acidic food packaging machine manufacturers liquids, like pasta sauces, won't interfere with The sleek operation of our products.

Calibration – Filling units need calibration checks every day in opposition to volumetric deviations and set focus on weights/volumes.

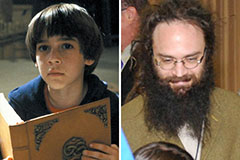

Barret Oliver Then & Now!

Barret Oliver Then & Now! Josh Saviano Then & Now!

Josh Saviano Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now!